The Leipzig Market Hall

Leipzig, Germany

1929

Span: 68.5 m

Reinforced concrete shells

Gabriella Figueroa, Thomas Mbise and Margaret Owensby

|

| Fig. 1: Front view of the Leipzig Market Hall as it is today |

The Need for a Marketplace

The 1920s were tumultuous years for Germany as a nation. Following German defeat in World War I, the economy under the Weimar Republic struggled due to the imposition of war reparations and rampant hyperinflation. However, with the institution of currency stabilization measures and foreign economic aid, by the middle of the decade the country was beginning to experience growth and recovery [1]. Leipzig was a city that was undergoing this gradual recovery process; after the war, its size had grown such that it had incorporated many of the towns that had formerly surrounded the city [2, 3]. Existing facilities within Leipzig were proving inadequate in serving the populace, so in the early 1920s city officials approved a proposal for a large public market space, or Grossmarkthalle, to accommodate and promote trade within Leipzig [3]. Designated as a space devoted solely to the sale of foodstuffs, the city officials chose to build the Market Hall on the city’s outskirts in order to avoid creating traffic problems within the main area of the city [4].

Dyckerhoff and Widmann (DYWIDAG) had gained its reputation and experience in designing and erecting vaulted reinforced concrete structures before World War I and was thus a good candidate for this project [5]. Some of its most famous works included the Centennial Hall in Breslau (1913) and the Carl Zeiss Planetarium in Jena (1922). It employed a cadre of engineers such as Franz Dischinger and Ulrich Finsterwalder who were experts in shell construction [6]. Design and execution of the Grossmarkthalle was entrusted to the municipal architect Hubert Ritter and the engineers Hubert Rüsch and Franz Dischinger.

Dischinger had begun working for Dyckerhoff & Widmann in 1913 [5]. At the time of the Market Hall’s construction, Dischinger also had considerable experience in the field of shell construction, as he had been involved with the construction of the planetarium in Jena, had written a mathematical treatise on domes [7], and was writing his doctorate thesis on polygonal domes [8]. He also worked on other aspects of shell theory, such as the development of equations that accurately described buckling in spheres, and he additionally sought to develop new kinds of shell shapes [6]. His partner for the project, Hubert Rüsch, had also done work concerning the topic of cylindrical shell analysis [5]. Therefore, it should come as no surprise that the choice was made to construct thin concrete domes to span the large distances required for a public marketplace.

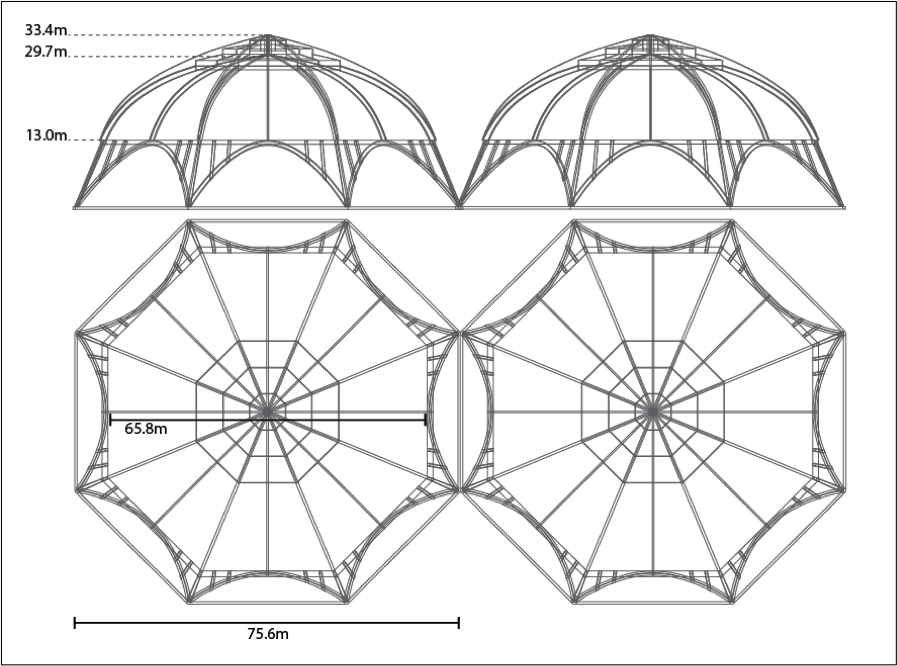

At their completion, the domes of the Leipzig Market Hall (Figure 1) each had a span of 65.8 m at the roof and 75 m at the foot of the building or foot of the arches [8] and together covered an area of 5700 m2 [9]. Although they may appear from the outside to be supported by the masonry structure that encloses the space around the bottom of the domes, the domes actually support their own weight with no aid from the rest of the building. Figure 2 shows a section and a top view of both of the domes. The domes rest on inclined pillars and arches, which, as seen in Figure 2, helped to increase the amount of surface area covered.

|

| Fig. 2: Section and Plan of the Leipzig Market Hall domes |

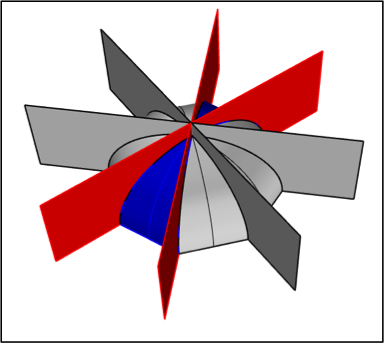

Derivation of Analytical Dome Shape

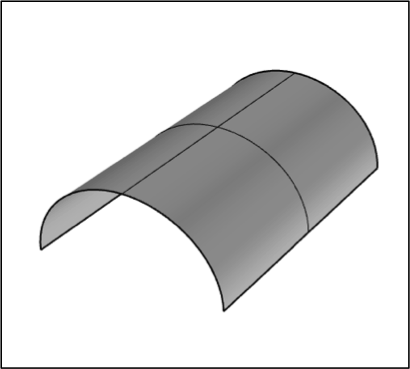

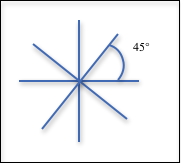

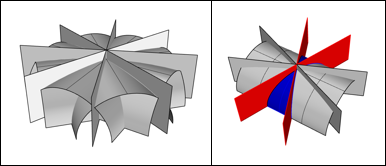

Dischinger’s and Dywidag’s design was conceived analytically, which means that the stress calculations for this structural shape had closed-form solutions. Another way to obtain the form of the domes is to begin with four cylindrical barrels sliced longitudinally. An example of one of these shells is shown in Figure 3a. The axis of each barrel can be taken as the line that goes through the center of the diameter of barrel. Placing the barrels such that the axes of the barrels make an angle of 45° with each other, as shown in Figure 4, produces the object in Figure 5.

|

|

|

| Fig. 3: Cylindrical barrel sliced longitudinally | Fig. 4: Plan view of intersection of axes of the four cylindrical barrels | Fig. 5: View of barrels when intersected 45° to each other |

It can be seen from Figure 5 that the intersections of the barrels form lines. Intersecting vertical planes with these lines, as seen in Figure 6a, allow one to find the required section of each barrel (Figure 6b). The required portion of the barrel (blue portion in Figure 6b) for the formation of the dome is the section of the barrel that is perpendicular to the axis of the barrel. By selecting the same portion for all the barrels, one obtains the shape of the entire dome (Figure 8). Figure 7 shows the dome with the portion of the barrel shown in Figure 6b.

|

| Fig. 6: 4 planes dividing the cylinders (b) Intersecting planes on one barrel and section to be included in the final dome (in blue) |

|

|

| Fig. 7: Required portions from each barrel with the intersecting planes. Portion of barrel in Figure 4b is shown in blue | Fig. 8: Final dome shape after removing intersecting planes |

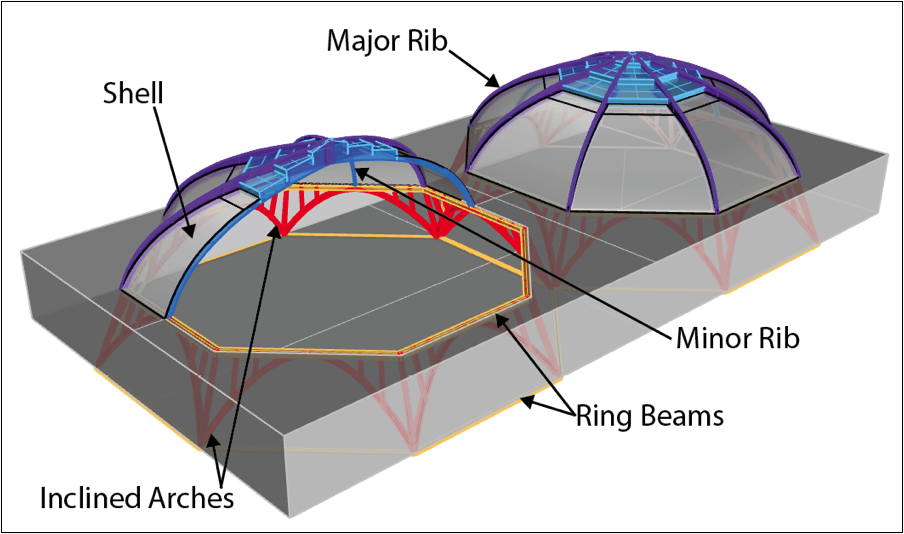

Structural Components and Flow of Forces

Each of the two polygonal domes has a structural system that consists of two ring beams, ties (not shown on figure), inclined arches and most importantly ribs for the dome that are extended into inclined columns. As previously noted, the domes do not simply sit on the horizontal roof of the masonry structure (represented in Figure 9 as the grey box underneath the domes), but have inclined pillars and arches that support them from inside the masonry building (see the cut in the dome in Figure 9). Although the flow of forces cannot be seen from the exterior of the structure, the inclined columns and arches reveal the structure’s ingenuity.

|

| Fig. 9: Structural elements of the dome system |

|

| Fig. 10: View of the interior one of the Leipzig domes with the parts labeled. Photo Courtesy of Prof. D. Billington |

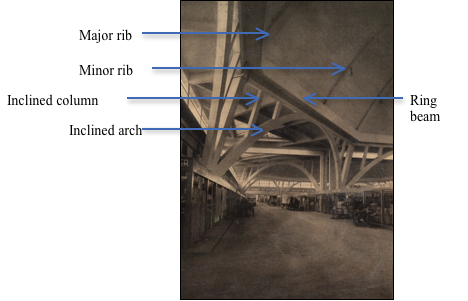

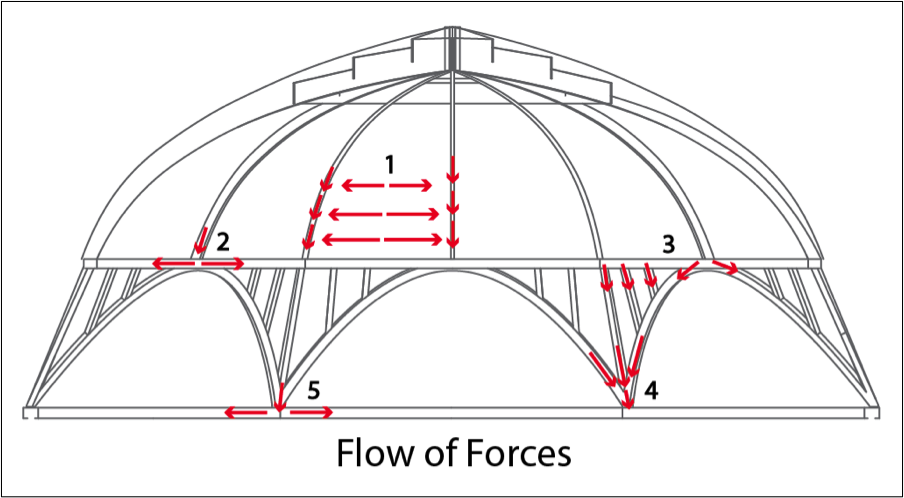

The loads on the shells, including self-weight, snow, and wind loads, are transferred to the main and minor ribs. Beams at the roof level (colored yellow in Figure 8) take some of the self-weight of the shell. The main ribs that are visible outside act as arches and exert a horizontal force on the flat roof (top of grey box in Figure 8). Some of the horizontal force is contained by the first ring beam which is also located at the flat roof but is not seen from outside. The rest of the horizontal forces are transferred to the bottom of the building through the inclined columns and arches where they are constrained by yet another ring beam in the basement and lateral ties [8]. The vertical forces from the roof are transferred downwards through the inclined columns and arches. Figure 10 is a photo of the interior with the parts labeled while Figure 11 shows the flow of forces in the entire structure.

|

| Fig. 11: Flow of forces in the dome |

Since the form of the Leipzig Market hall was developed from the intersection of pipes or barrel vaults, it is helpful to explore the some of the properties of this shape. Another construction project completed by Dyckerhoff and Widmann was the Frankfurt Market Hall [9], which consisted of cylindrical shells or barrel vaults (which always have single curvature) lined up next to each other. The method of construction of the domes, called the Zeiss-Dywidag method, allowed for the roofing of large areas without the need for intrusive intermediate supports and proved to be economical, efficient and aesthetically pleasing [10]. The amount of material used was economical due to the fact the shell under its own load has to resist normal stresses but not bending moments [10]. The absence of bending moments under dead load eliminates the need to have thicker shells since the greater the bending moments under dead load the greater the thickness required to resist them. Stress is defined as a force divided by the area over which the force is acting. If we take an element like the one shown in Figure 12, normal stresses will be caused by forces horizontal to the vertical surface of the element. Shear forces, acting parallel to the vertical surface of the element in Figure 12, will cause shear stresses. Bending moments can be represented as a conjugate pair of forces, and they are always present when an element is made to deflect without moving its supports. Moments can be measured as a force times the distance from the point at which the force is applied to the point at which the moment is being determined.

|

| Fig. 12: Element with normal forces (horizontal arrows), shear forces (vertical arrows) and bending moments (curved arrows) |

Given the advantages of cylindrical shells, it seems clear why cylindrical pipes were the core elements in obtaining the form of the Leipzig Market Hall. When trying to cover an irregular area, engineers would intersect domes and combine vaults in order to determine the exact shape that was needed [10].

Design and Construction

From the early 1910’s until the late 1930’s, many structural engineers in Europe looked at shell structures with interest [6]. Concrete shells in particular were admired because they spanned very large distances, used less material, and cost less than other options. The easiest way to see their material and cost efficiency is through their ability to span greater distances without the need of intermediate columns, which would require more material. Developments in concrete prestressing and reinforcement, and also the development of stronger steel rebar, were primarily responsible for the newfound ability to design and build these shells [11]. Thin shells were additionally seen as a sound design choice because when shaped correctly, they experienced little to no bending moment, and any compression that was found within the shell was uniformly distributed [10]. The domes of the Leipzig Market Hall only had a thickness of 9 cm [17]. Although the value of the concrete cover in the domes is not known, if they had been built in accordance with code by the American Concrete Institute, they would have a cover of approximately 1.9 centimeters (0.75 inches). Due to the small thickness, the stresses of most concern within a shell were normal stresses, which could cause buckling. The need to prevent buckling led to a need for a small dead load, which was conducive for the construction of shells with very small thicknesses [11]. Unlike many who designed and built concrete shells later in the twentieth century through methods such as form-finding, the early shell pioneers were known for their intensively analytical design practices; many of the engineers who worked at DYWIDAG, including Dischinger, had personally developed the equations and methods by which thin shells could be optimized and constructed [5].

Although the municipal architect Hubert Ritter had drawn up the plans, it was in fact Dischinger who designed the polygonal domes [9]. The obvious question to ask at this point is: why wasn’t a spherical dome used instead, since conceptually it seems to have a simpler shape? Moreover, the Carl Zeiss Planetarium in Jena built in 1922 had a spherical dome. The fact of the matter is that building a spherical dome over a polygonal area posed great construction difficulties at the time [8].

Although he relied heavily on analytical methods to analyze his design, Dischinger also built a physical model that was one-sixtieth the size of the Leipzig Market Hall to confirm the results he obtained on paper [8]. Initially Dischinger did not include the minor ribs, but after running tests on the physical model he realized that the shells needed extra support and thus ended up adding the minor ribs [8].

The Leipzig Market Hall shells were then constructed using the Zeiss-Dywidag method. The firms Dyckerhoff and Widmann (DYWIDAG) and the Carl Zeiss Company had patented the approach- thus it was called the Zeiss-Dywidag method. The firms obtained the patent after the construction of a test dome that Carl Zeiss wanted to build as an extension of the German Museum in Munich [5]. This process involved the construction of a framework of rigid and self-supporting steel bars that divided the desired shape into a number of polygonal shapes, which were then wrapped in wire mesh. Workers then sprayed a thin layer of gunite, a type of concrete [12], onto this system [13], with formwork “used as a backing to prevent spray-through” [6]. Once the concrete had dried, the formwork was removed and used for the next section of the shell that was to be sprayed with concrete. Figure 13 is a photograph of the setup of the Zeiss network for the Basel dome, which is similar to the Leipzig domes. There were many benefits to the Zeiss-Dywidag method. Firstly, it helped the builders overcome some of the problems associated with the curvature of the surface [6]. The use of Zeiss-Dywidag also allowed the builders to reduce the cost of construction, not only due to the fact that the thinness of the shell meant that less material was used, but also because the shell formwork could be reused. The use of the steel formwork had the added benefit of greatly simplifying the shape of the structure, which made the building process easier and cheaper. And since the method allowed the shell to span a very large area without the need for columns in the middle of the structure, an open, aesthetically pleasing space was created under the domes of the Grossmarkthalle [10].

|

| Fig. 13: Setting up of the Zeiss network for the Basel dome (in Switzerland) in the patented Zeiss-Dywidag construction method. The Basel dome is structurally similar to the Leipzig domes. Photo Courtesy of Prof. D. Billington |

This solution is further appreciated after examining the other alternatives for the Market Hall that were considered during the initial design phase. The chosen option included three domes and 24 inclined pillars in total, but the first option was a flat roof with 88 columns. The second included 35 columns with adjacent cylindrical shells like the Frankfurt Market Hall [9]. It can be seen that the use of the domes eliminated the need to build several intermediate columns that would have reduced the span of open space.

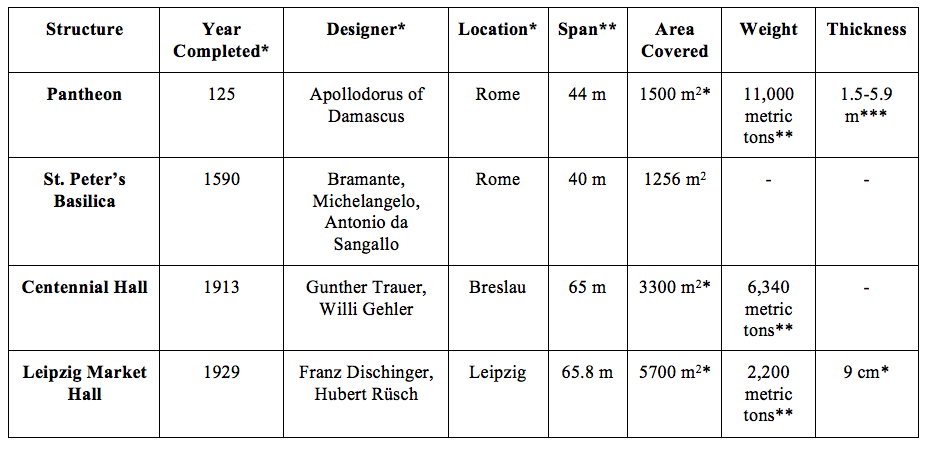

Although the plan initially was to build three domes with the third being an extension, only two octagonal domes were built [8]. When the project was completed in 1929, each dome had a span of 65.8 meters at the point where the dome connects with the roof of the building. But structurally, oblique arches in the building’s interior support the dome. Since the bases of these arches extend outward from the dome, the span of the dome including the interior arch supports is approximately 75 m. At the time, this was the largest span of any dome structure in the world, surpassing the previous record holder, the Centennial Hall in Breslau (1913), by approximately a meter. Another particularly impressive aspect of the Market Hall is the fact that despite having a greater span than the Centennial Hall, each dome of the Market Hall has a weight of roughly one-third of that of the Centennial Hall dome. A comparison with important domes from throughout history that were renowned for their large spans (see Table 1) confirms that not only does the Leipzig Market Hall have the greatest span of 75.6 m, but it is also by far the lightest (2,200 metric tons) and thinnest (9cm) of these structures. This bears witness to the remarkable efficiency and economy of Dischinger’s design. In 1957, the span of the Belgrade Fair – Hall 1 (109 m) in present-day Serbia beat the span of the Leipzig domes. Although the record of the span of the Leipzig domes was broken, it still was by then the largest span built with reinforced concrete. The Belgrade Fair dome was built with prestressed concrete, a new technology at the time, which stressed the steel reinforcing bars prior to load application. This allowed them to take on larger loads.

|

| Table. 1: Comparison of dimensions and properties important domes Sources: * References [14], [15], [16], [17] ** Reference [9] *** Reference [20] |

Most indoor spaces need to be built considering lighting and heating. The best structures must account for these factors during the design process in order to ensure that the building is economical in the long term. In the Market Hall, a 5 cm layer of cork was added on the mortar on the exterior side of the dome for thermal insulation [8]. For lighting purposes, a skylight was a permanent solution. The inclusion of the skylight, which has a diameter of 28 m [8], allows light in and reduces cost of lighting the domes. Making the skylight 3 m high (Figure 2) allowed it to have a greater surface area and hence allows more light in. The inclusion of the skylight and thermal insulation had the added and perhaps unintentional advantage of achieving energy efficiency, a concept which was not truly conceived until later in the twentieth century. It may also be said to fulfill an aesthetic purpose, as it hearkens back to the oculi that are found in other renowned domes like the Pantheon. This indicates that great care was taken by the designers to produce a structure that successfully integrates the practical demands of the form, function, and immediate environment of the structure, while still accounting for the aesthetic aspect of the design.

Post-construction until the Present Day

The Grossmarkthalle in Leipzig was one of a series of thin-shell marketplaces that Dischinger helped to design and build in Europe from the 1920s until 1940. The Grossmarkthalle constructed in Basel, Switzerland (Figure 10), also completed in 1929, was quite similar to the Leipzig Market Hall in that it featured an octagonal, ribbed, and steel-reinforced concrete dome. It had a span of 60 m and the thickness of the reinforced concrete shells was 8 cm [19]. The Basel Market Hall lacked inclined arches and columns on the arches. Other projects, such as the Market Halls in Frankfurt (1928) and Cologne (1940), were designed with thin, singly-curved concrete barrel vaults [7]. The fact that a number of these thin-shell structures were built throughout Central Europe solely for utilitarian reasons and still stand to this day serves as a testament to their efficiency and sound design.

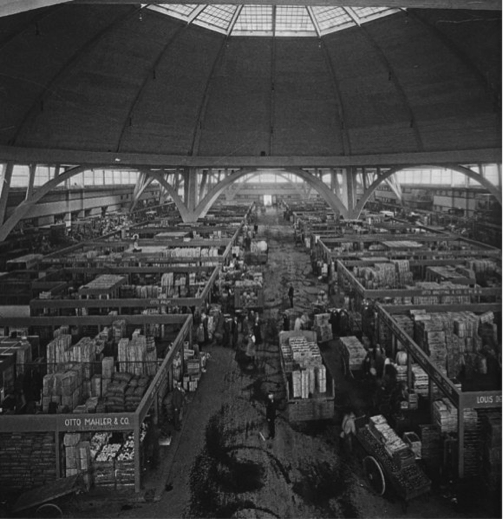

The Leipzig Market Hall, originally built as a marketplace for fruits and vegetables (Figure 14), continued to be used in that capacity until 1994. In 2000, when the building was over seventy years old, the entire Hall was renovated, and the structure was put to new use. Today, the north cupola is used as a multipurpose venue that hosts concerts, theater events, circuses, and other events [21]. The southern dome was transformed into a skating rink that is open during the winter months, and now known simply as the “Eisdom.” The entire complex currently goes by the name “Kohlrabizirkus” [21]. Unfortunately, a visit to the Market Hall today reveals a building that perhaps has not received proper maintenance in a number of years; portions of the structure are covered in graffiti and have fallen into disrepair (Figure 15). However, the fact that the domes appear to be structurally intact serves as convincing evidence of the skill of the German designers and engineers at the time. Shell designers would later come to use physical and computational models to obtain shell forms that would not require closed-form solutions. Heinz Isler, Felix Candela and Jorg Schlaich are among these later designers, and they successfully carried on the legacy of the early German shell pioneers, albeit through different design methods. Nevertheless, the unique analytical derivation of the shells of the Leipzig Grossmarkthalle places it among the greatest and most innovative shell structures of all time.

|

| Fig. 14: The Market Hall being used for its original purpose, providing a space for the sale of fruit and vegetables in Leipzig (Photo Courtesy of Prof. D. Billington) |

|

| Fig. 15: Graffiti on the dome and backside of the Market Hall |

[1] Tipton, Frank B. (2003). A History of Modern Germany Since 1815, University of California Press, Berkeley, CA, 332-333.

[2] Reich Statistical Office (ed.). Statistical Yearbook of the German Reich, 1919-1941/42.

[3] Maigrot, Emile. (1929). “Halles du marché de gros de Leipzig,” L’Architecture 42(1), 9-12.

[4] Anonymous. (1933). “Leipzig Market Hall,” The Architect and Building News 136, 38-139.

[5] Hines, Eric M., and David P. Billington. (2005). “Anton Tedesko and the Introduction of Thin Shell Concrete Roofs in the United States,” Journal of Structural Engineering, November 2005, 1639-1641.

[6] Bechthold, Martin. (2008). Innovative Surface Structures: Technology and Applications, Taylor and Francis Group, New York, 34-35.

[7] Abel, John. (2012). “German Shell Builders,” Sept. 20, 2012, Lecture given at Princeton University, Princeton, NJ.

[8] Picon, Antoine. (1997). L’Art de l’Ingenieur: Constructeur, Entrepreneur, Inventeur, Centre Georges Pompidou, Paris, 150, 261-262.

[9] Anonymous. (1929). “Les coupoles du nouveau marché de Leipzig,” La Technique des Travaux 5(10), 559-568.

[10] Anonymous. (1932). “Introduce New Type of Roof Construction," Railway Age (1918-1988), 93(1), 21.

[11] Mungan, Ihsan, and John F. Abel. (2012). “Towards Lightness in Concrete: Some 20th Century Shells and Bridges,” Journal of the International Association for Shell and Spatial Structures 53(2) n. 172, 75.

[12] “Gunite,” MerriamWebster.com, <http://www.merriam- webster.com/dictionary/gunite> (Dec. 1, 2012).

[13] International Congress. (1985). “Theory and Experimental Investigation of Spatial Structures: Application of Shells in Engineering Structures” Moscow, USSR, 23-28 September 1985, 160.

[14] “Pantheon.” Structurae, <http://en.structurae.de/structures/data/index.cfm?id=s0000292> (Nov. 7, 2012).

[15] “St. Peter’s Basilica.” Structurae, <http://en.structurae.de/structures/data/index.cfm?id=s0001062> (Nov. 7, 2012).

[16] “Century Hall.” Structurae, <http://en.structurae.de/structures/data/index.cfm?id=s0000363> (Nov. 7, 2012).

[17] “Leipzig Market Hall.” Structurae, <http://en.structurae.de/structures/data/index.cfm?id=s0000042> (Nov. 7, 2012).

[18] “Belgrade Fair – Hall 1.” Structurae, <http://en.structurae.de/structures/data/index.cfm?id=s0057675 > (Dec. 17, 2012).

[19] “Großmarkthalle Basel.” Structurae, <http://en.structurae.de/structures/data/index.cfm?id=s0010845> (Dec. 17, 2012).

[20] “Historic Domes,” NISEE, Pacific Earthquake Engineering Research Center, University of California at Berkeley, <http://nisee.berkeley.edu/elibrary/getpkg?id=GoddenE2-22> (Nov. 5, 2012).

[21] “Historical Facts.” Kohlrabizirkus-Leipzig.de, <http://www.kohlrabizirkus-p leipzig.de/framesete.htm> (Oct. 20, 2012).